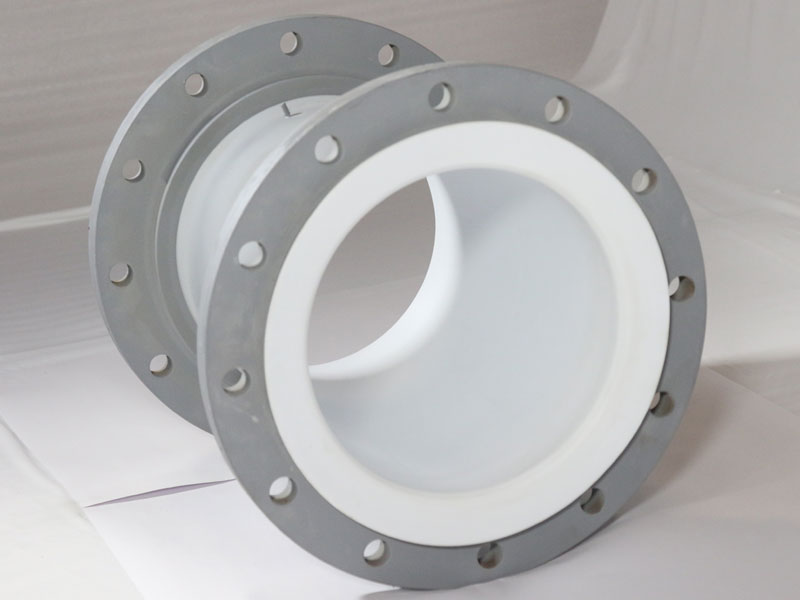

Lined Piping Systems

Lined Piping Systems

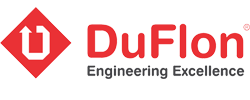

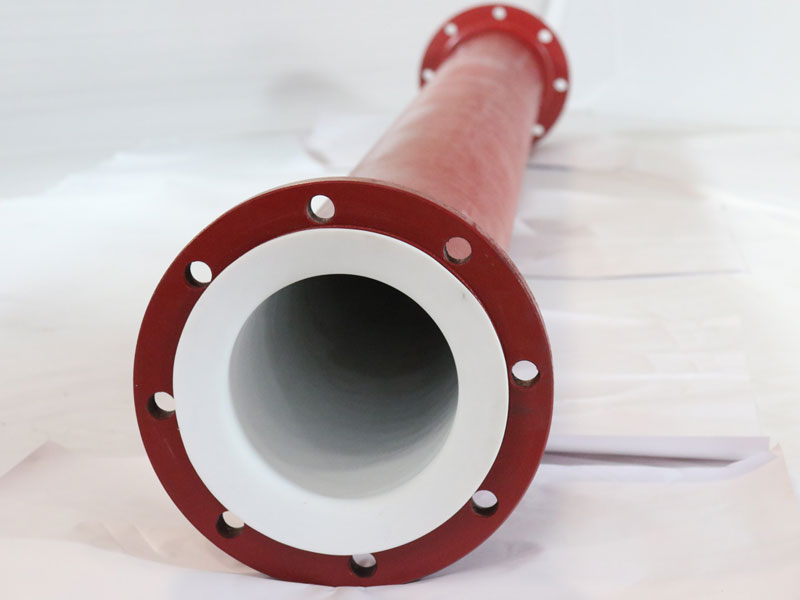

This Business Division was started in 2003, with just one purpose in mind: To enable customers in their quest to fight Corrosion. Lined Spools and Fittings are manufactured specifically for use in corrosive environments. Lined Piping Systems (LPS) are standard products manufactures according to ASTM, DIN, IS standards..These pipes and fittings are manufactured in full compliance with ASTM F 1545, Standard specifications for plastic lined ferrous metal pipe, fittings and flanges. Dufline products are available in a variety of steel grades and lined with fluoropolymers like PTFE (Polytetrafluoroethylene) /PFA (Perfluoro Alkoxy) /PP (Polypropylene). DuFlon offers “TYPE Tested” products. Adhering to International Standards, DufLine products undergo rigorous inspection at various stages beginning from raw material inspection, in-process inspection, Hydro test, Spark tests, Dimension test and Visual test right up-to final manufactured product. Traceability of materials and tests conducted are also maintained. Special products such as Flow Meters are also made. To match the increasing demand for high quality Corrosion Resistant Products, DufLine has diversified further into lining of Vessels, Columns and Tanks as well as Coating Solutions.

Expansion Joints

Expansion Joints

Duflon Expansion joints are 100% roll tested before molded into convoluted form. In this test, the liner is compressed to 50% of its diameter in two different planes to detect liner defects.Duflon expansion joints are 100% hydrostatically tested prior to shipping. This ensures that The final product is free from defects. All expansion joints are hydrostatically tested at 1.5 times their Pressure rating.

One expansion joint of each size is installed at neutral length on the flex tester and is flexed at allowable compression and extension. One cycle is defined as neutral-compression-neutral-extension-neutral.

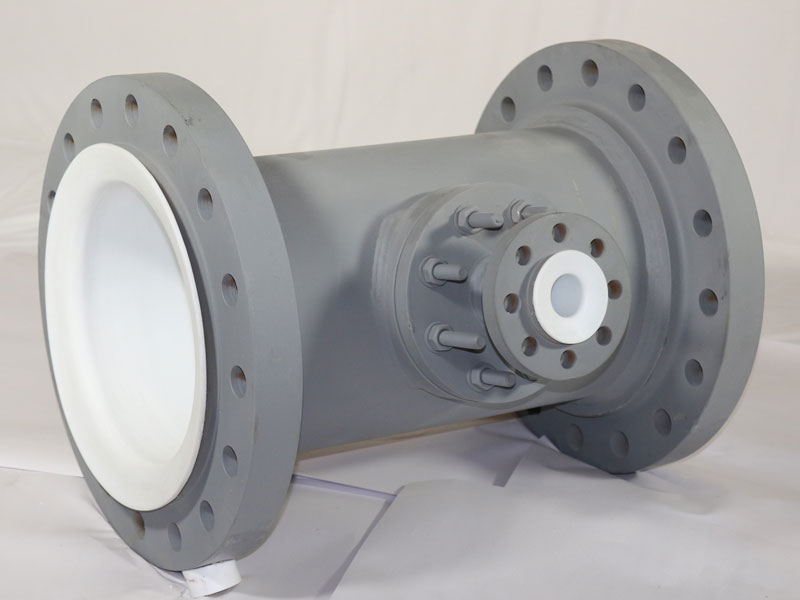

Dip Pipe

Dip Pipe

DufLine dip pipes have a wide array of uses. Typically they are used to charge a reactor below the liquid level, to extract samples from the reactor as part of one of our sampling systems, Or to drain liquid from a vessel without the need of side or bottom outlet.DufLine dip pipes are manufactured from a carbon steel fabricated construction with a continuously lined paste extrusion PTFE liner. Having all wetted parts in PTFE gives excellent corrosion resistance.

Dip pipes can be supplied straight or curved to angle liquor to the side of the reactor etc..

Powerful agitator blades can create a lot of stress on components installed in a reactor vessel. Before we supply any dip pipes we thoroughly check that the mechanical strength of the dip pipe will be sound against.

The specific process conditions. This is extremely important to save on very costly breakages.

| Standard Housing Materials | Body: CS ASTM A106 Grd.B 1” to 8” (Sch. 40),10” to 12” (Sch 30).Also available : 304/316 Stainless Steel |

|---|---|

| Standard Flange Materials | As per ASTM A105. Dimension as per ANSI B 16.5 Class150, Class300. |

| Standard Liner Materials | PTFE as per ASTM D 4895, Lining and testing as per ASTM F1545-15a |

| Exterior Finish | Standard: Two Layers of epoxy corrosion Resistant primer. Special paint or blast profile can be applied for an additional charge. |

Equipment Lining

Equipment Lining

| Standard Housing Materials | Pipe: 1” to 8” (Sch. 40) , 10” to 12” (Sch 30) CS ASTM A106 Grd B, Also available : 304/316 Stainless Steel |

|---|---|

| Standard Flange Materials | As per ASTM A105. Dimension as per ANSI B 16.5 Class150, Class300. |

| Standard Liner Materials | PFA as per ASTM D 4895. Lining and testing as per ASTM F1545-15a |

| Exterior Finish | Standard: Two Layers of epoxy corrosion Resistant primer. Special paint or blast profile can be applied for an additional charge. |